CAPSTAN is one of a main part in wire drawing factories.

There are available in many forms. They can be made from Ductile Iron, Low Alloy Steel. High wear area is where wire is draw passing capstan. This is a Sliding Wear.

By carefully select material to resurfacing the worn-out area and suitable method to do this, the initial cost might be higher, but your total cost will be much lower. Your profit will be higher!

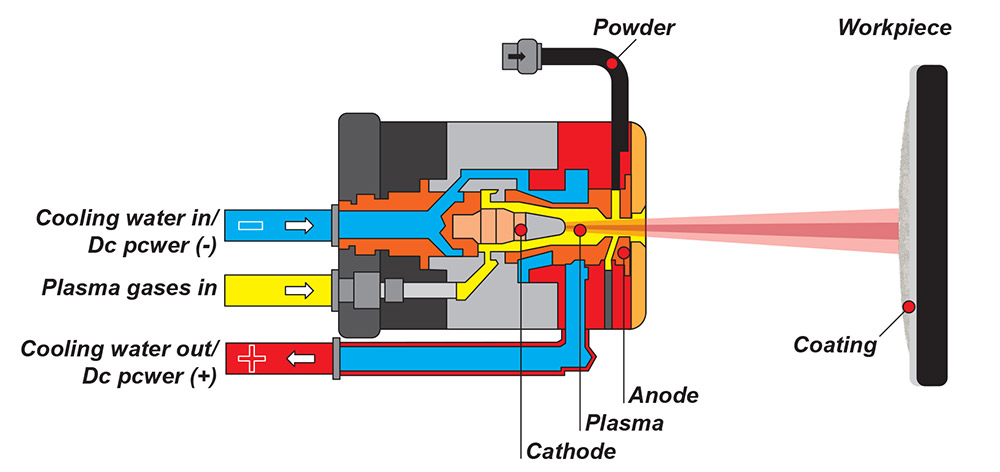

Plasma Spray Coating

Resurfacing methods:

- Shielded Metal Arc

- Flux-cored wire welding

- Wire Arc coating

- High Velocity Oxy-Fuel Coating

- Plasma Spraying

Materials for Resurfacing

High Alloys Steel:

- Chromium (Cr)

- Niobium (Nb)

- Molybdenum (Mo)

- Cobalt (Co)

Carbides:

- Tungsten Carbide (WC)

- Chromium Carbide (Cr3C2)

- Titanium Carbide (TiC)

- Molybdenum Carbide (Mo2C)

- Boron Carbide (B4C)

- Silicon Carbide (SiC)

Oxides:

- Chromium Oxide (Cr2O3)

- Titanium Dioxide (TiO2)

- Aluminium Oxide (Al2O3)

- Zirconium Dioxide (ZrO2)

- Magnesium Oxide (MgO)

Plasma Spray Coating

Special Characteristics of Plasma Spray Coating

- Micro Grain Structure.

- Very low porosity

- High temperature for Advanced Ceramics.

- High bonding strength.